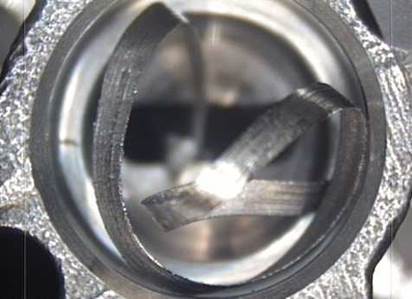

First 3D metal printer at Extrude Hone – Holzgünz, DE.

Shaping and Finishing Solutions. Stay tune for more Extrude Hone and 3D metal printing news.

LAI INTERNATIONAL LEADING THE CUTTING EDGE

You’ve probably all heard by now of Extrude Hone’s claims to the benefits of Abrasive Flow Machining (AFM) and our latest technology COOLPULSE in the 3D printed market. Why just take our word for it though? (more…)

Improving firearm reliability, accuracy, and performance

Extrude Hone is the unique Contract shop providing ECM rifling in America, but that’s not all.

ECM – The perfect heart beat makes the difference

Select the right generator technology for your Electrochemical Machining (ECM) Solution. (more…)

Thermal Deburring – knowing which burrs can be BLASTED.

Manufacturers of manifolds or parts with intersected holes – Learn which burrs are suitable for thermal deburring (TEM). (more…)

Extrude Hone presents today at the INSECT

COOLPULSE: The breakthrough for additive manufactured parts. We are delighted to participate in the 13th International Symposium on Electrochemical Machining Technology ( INSECT ). (more…)