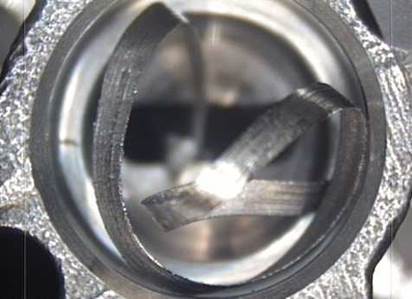

Thermal Deburring – knowing which burrs can be BLASTED.

Manufacturers of manifolds or parts with intersected holes – Learn which burrs are suitable for thermal deburring (TEM).

As manufacturing processes continue to become more and more demanding, greater focus is put on burrs and their removal from components. Whether you have a manifold for the automotive, aerospace or energy market, the presence of burrs can make the difference between securing a contract or a missed opportunity. As always, with more stringent practices, the key is to minimize the increasing costs to keep your parts affordable in an ever-competitive market.

So, what are your options? Manual picking? Brushing? Something else, perhaps?

Here at EXTRUDE HONE, we believe we have the answer. Using our cost-effective method, Thermal Deburring (well-known as TEM), you can quickly process your parts to a burr free condition!

But TEM is not a magic wand that will remove any burr regardless of condition.

We have put together a white paper to highlight various burr conditions and help you identify what will work and what will not.

Please click below to learn more about the capabilities of TEM, its limitations, and how it could help you as a manufacturer with your particular burr challenges

For information on our TEM technology: