EXTRUDE HONE TO BE FEATURED AT MIT

July 31 to August 4, MIT will be hosting an Additive Manufacturing course to cover the manufacturing and processing of 3D printed parts and has asked Extrude Hone to showcase parts processed with our AFM and COOLPULSE technologies! (more…)

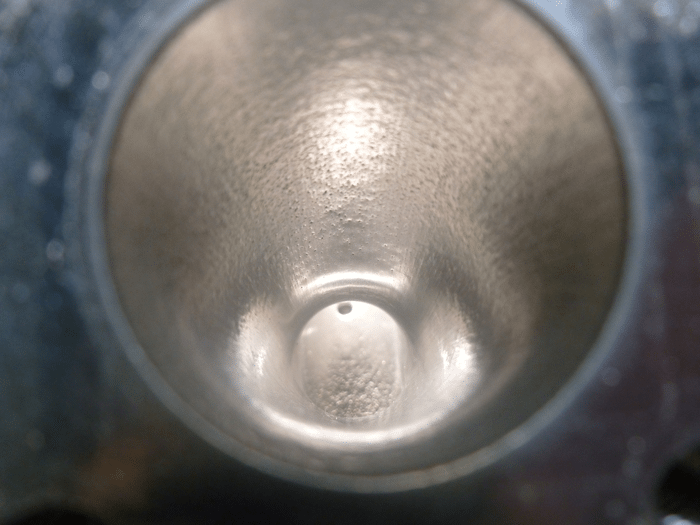

K factor a critical parameter in Fuel System nozzle finishing.

As a supplier of fuel nozzles for next generation engines and components, you’re aware of the increasing emphasis to decrease fuel consumption and emissions through the increase of injection system pressures. The goal being to achieve a greater atomization of the fuel as it enters the engine. (more…)

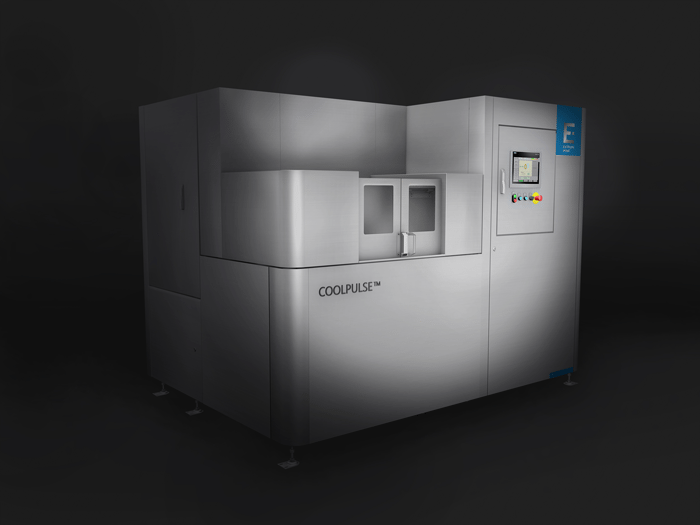

COOLPULSE Finishing Solutions for Metal 3D Printed Parts & More – Paris Air Show.

EXTRUDE HONE is pleased to welcome you to our stand at the Paris Air Show, taking place June 19th to 23rd. You`ll find us in Hall 3 Booth D29.

Let’s focus on our new COOLPULSE Technology for surface finishing of metal 3D printed parts. (more…)

Abrasive flow machining solutions for 3D printed components with internal passages – Paris Air Show.

EXTRUDE HONE is pleased to welcome you to our stand at the Paris Air Show, taking place June 19th to 23rd. You`ll find us in Hall 3 Booth D29.

AFM meets the polishing needs of internal surfaces and intricate passages. (more…)

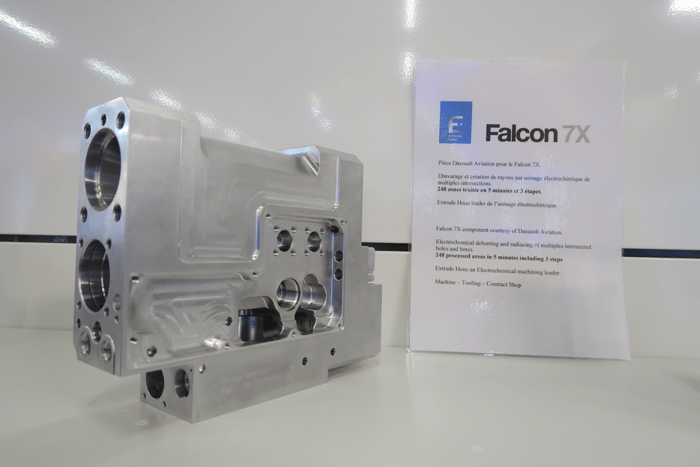

Electrochemical finishing solutions for Falcon 7X aero manifold – Paris Air Show.

EXTRUDE HONE is pleased to welcome you to our stand at the Paris Air Show, taking place June 19th to 23rd. You`ll find us in Hall 3 Booth D29.

Let’s focus on the Falcon 7X component displayed on our booth courtesy of Dassault Aviation. (more…)

Subcon 2017

Visit Extrude Hone at the Subcon Expo at the NEC in Birmingham, June 6 – 8. We will be set up at Stand G10. We look forward to the opportunity to meet everyone!

Extrude Hone at the Paris Air Show Hall H3 Booth D29

AFM, MICROFLOW, and COOLPULSE™ finishing solutions for inner and outer metal 3D printed component surfaces.

For many years Extrude Hone has helped the aerospace industry to improve surfaces.

Now Extrude Hone continues that mission to address the new challenges surrounding 3D printed components.

Surface improvement for metal 3D printed parts is always a challenge and getting the right solution brings a component within the realms of being truly functional. (more…)

EXTRUDE HONE® TECHNOLOGY DAYS FREE INVITE

EXTRUDE HONE® TECHNOLOGY DAYS FREE INVITE

Holzgünz Germany, May 17- 18, 2017

-

International Speakers:

Offering visitors the opportunity to hear from Universities, Institutes and key players from the 3D Printing world from different angles.

-

Demonstration:

Live finishing performance using 3D printed samples, and with the following technologies: COOLPULSE™ , AFM, Dynamic ECM, PECM.

-

World Premiere:

COOLPULSE™

by EXTRUDE HONE®, introducing THE solution for 3D printed part finishing.

[dt_button url=”http://discover.extrudehone.com/COOLPULSE” style=”link” size=”btn-default” skin=”dark” target=”_blank”]Register Free[/dt_button]

Enhanced Finishing Solution for metal 3D printed components

Additive Manufacturing

There is extreme interest revolving around Additive Manufacturing. Fully functioning cars were produced using Additive Manufacturing techniques during the 2016 IMTS Show in Chicago – demonstrating the process benefits of the AM Technology.

Additive manufacturing (known also under DLMS; SLM; AM, ALM, 3D Printing) is a process of building parts and components layer by layer, connecting powder particles via an energy source. (more…)