EXTRUDE HONE IMTS MACHINE SPECIAL

AS A SPECIAL FOR IMTS EXTRUDE HONE IS OFFERING REDUCED PRICING ON A C250 – THERMAL DEBURRING – MACHINE!

ECO+ WHEN ONLY THE BEST IS GOOD ENOUGH

ECO+, our NEW modular standard machines – versatility without compromise! (more…)

ECO+ NEW MODULAR ECM ENTRY LEVEL MACHINE

ECO+ With our new entry level standard ECM machine we help you to provide the edge. (more…)

JOIN US AT THE RAPID/TECH IN ERFURT GERMANY Booth 2-813

Let’s talk about finishing of 3D printed parts with a special focus on our Technologies, AFM and COOLPULSE; and our latest product finish3D.

JOIN US AT THE 3D PRINT IN LYON FRANCE Booth E17

Vincent Grimm from Extrude Hone will conduct a workshop on Wednesday June 6th between 10:40am and 11:10am on “How to improve roughness of 3D printed parts”; focusing on our Technologies AFM and COOLPULSE; and our latest product finish3D.

EXTRUDE HONE HOSTS EWI CONSORTIUM TOUR

Extrude Hone wishes to extend a huge thank you to EWI’s Additive Manufacturing Consortium and its participating members! (more…)

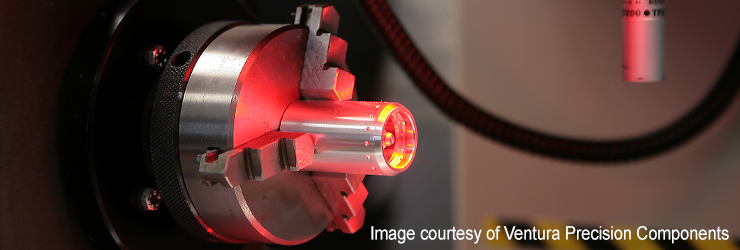

Electrochemical Machining (ECM) for Automotive Braking System Components

How Ventura Precision Components Leverage ECM in Next Generation Brake Piston Production

(Video) Extrude Hone and MMP Technology present finish3D

Taking Surface Finish to a NEW Dimension (more…)

EXTRUDE HONE FEATURED IN ADDITIVE MANUFACTURING

Leading up to this year’s RAPID +TCT show, Extrude Hone’s COOLPULSE technology was recently selected to be featured in the March Edition of Additive Manufacturing!

(Video) COOLPULSE

EXTRUDE HONE’s technology is an enhanced finishing solution for metal 3D printed parts, also referred to as Additive Layer Manufacturing (ALM) components. COOLPULSE technology solves the problem of rough surfaces by keeping the Freedom of Design for metal parts at once! This new technology allows complete surface treatment and sets a milestone in development of ECM (Electrochemical machining).