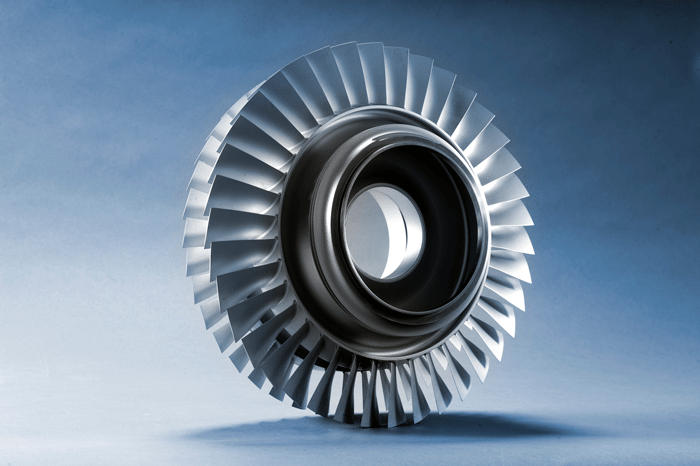

ITP Engines is adapting AFM for reliable finishing of blisks.

How ITP Engines UK and partners Brunel University and ExtrudeHone team up to get a mathematical model of the AFM process to size in the complex geometries of blisks.

EXTRUDE HONE TO BE FEATURED AT MIT

July 31 to August 4, MIT will be hosting an Additive Manufacturing course to cover the manufacturing and processing of 3D printed parts and has asked Extrude Hone to showcase parts processed with our AFM and COOLPULSE technologies! (more…)

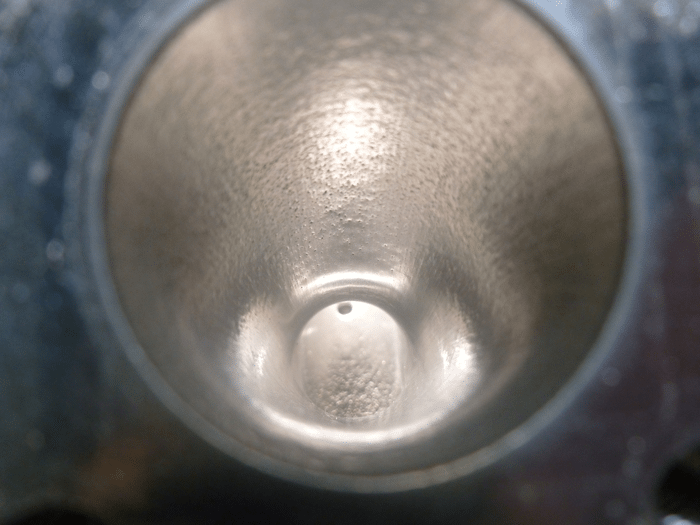

Abrasive flow machining solutions for 3D printed components with internal passages – Paris Air Show.

EXTRUDE HONE is pleased to welcome you to our stand at the Paris Air Show, taking place June 19th to 23rd. You`ll find us in Hall 3 Booth D29.

AFM meets the polishing needs of internal surfaces and intricate passages. (more…)

Subcon 2017

Visit Extrude Hone at the Subcon Expo at the NEC in Birmingham, June 6 – 8. We will be set up at Stand G10. We look forward to the opportunity to meet everyone!

New Thermal Deburring Machine by Extrude Hone

New thermal deburring machine. Extrude Hone brings – the T350 and T450 thermal deburring machines to  provide quick reliable solution for complete and simultaneous removal of internal and external burrs.

provide quick reliable solution for complete and simultaneous removal of internal and external burrs.

The challenges:

- To have reliable hydraulic manifolds

- Improved quality by 100% removal of lose burrs, attached burrs and other particles

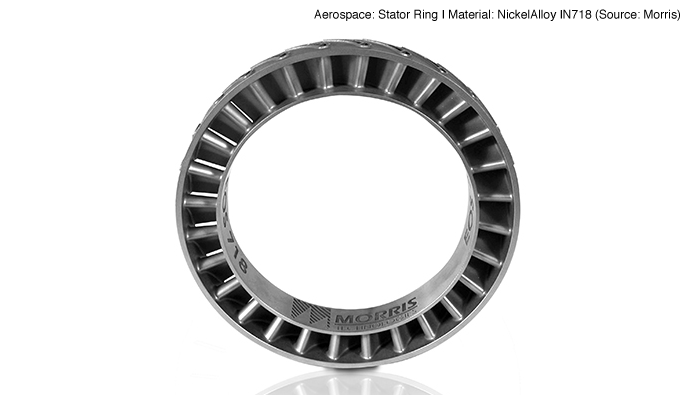

AFM: High-Quality Finishing for Industrial 3D Printing

As 3D printers become more ubiquitous, the question manufacturers are trying to answer is not ‘how do we incorporated industrial 3D printing?’ but ‘how do we incorporate industrial 3D printing better than our competitors?’ Whether your application involves additive layer manufacturing (ALM) or laser sintering, the key that can set your

product above the rest is finishing. (more…)

SubCon 40th Anniversary

We at Extrude Hone are excited to participate in this year’s SubCon at NEC Birmingham, June 7-9. Celebrating its 40th anniversary, SubCon is the UK’s premier manufacturing supply chain show and is dedicated to outsourced engineering services and subcontracting.

SubCon’s British and international exhibitors cover all sectors of the manufacturing supply chain: automotive, aerospace, electronics, energy, rail, oil and gas, and defense and security, plus — new this year — dedicated zones for software and for materials and composites. Also new this year, the conference’s Buyer’s Programme lets you book appointments with the exhibitors you’re most interested in before the conference even begins. This can give you a personalized SubCon experience that makes the most efficient and effective use of your time.

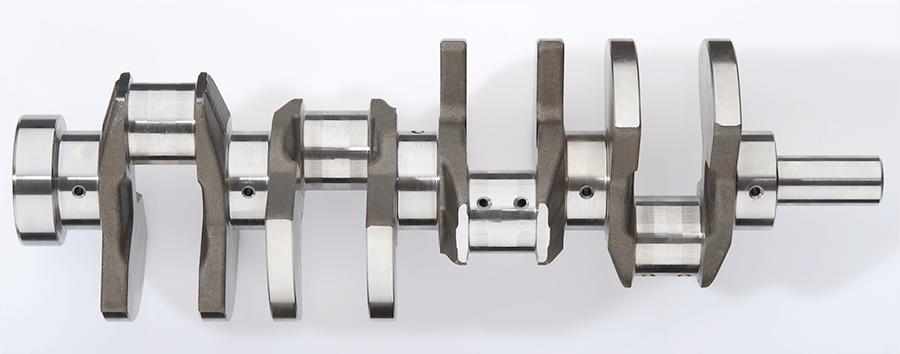

Improving Crankshaft Manufacturing

Improving Crankshaft Manufacturing with Electrochemical Machining

Ensuring sufficient and permanent lubrication of crankshaft bearings in automobile engines is critical for avoiding engine failures. As the crankshaft becomes smaller, due to manufacturing trends and consumer expectations, the number of oil intersection holes increases. All burrs and debris left behind in the drilling process must be removed.

New Microflow Highflow

EXTRUDE HONE brings all new MICROFLOW HIGHFLOW solution to meet the high precision flow targeting system requirements of the heavy-duty market (Marine, trucks, off-highway, and diesel power generators).

The challenges:

With climate changes posing significant risk to the society, reducing the fuel consumption and emissions is one of the critical steps in slowing the negative effects of climate change. Medium and heavy-duty vehicles represent a significantly smaller fraction of the number of vehicles on the road but still contribute to more than one-fifth of emissions. Figure 1 represents the stringent emission standards OEMs in the heavy-duty vehicles market face leading to the following challenges: (more…)

Make in India Movement Promises New Future.

Drawing on the combined power, foresight, and expertise of politicians, entrepreneurs, investors, and industry leaders, the Make in India movement hopes to turn the largest democracy in the world into a manufacturing and design hub, sparking new growth and international investment and inspiring confidence in India’s capabilities.

At the beginning of the 21st century, India showed great promise as an emerging market, but by 2013, its growth rate had fallen to the lowest in a decade. Recognizing that part of the problem was government bottlenecks, Prime Minister Nerendra Modi set out to overhaul government policies and procedures to allow businesses more room to thrive. The ultimate goal was a mindset of “minimum government, maximum governance.”