THERMAL DEBURRING (TEM) SOLUTION FOR SHAFTS– DEBURRING EXPO

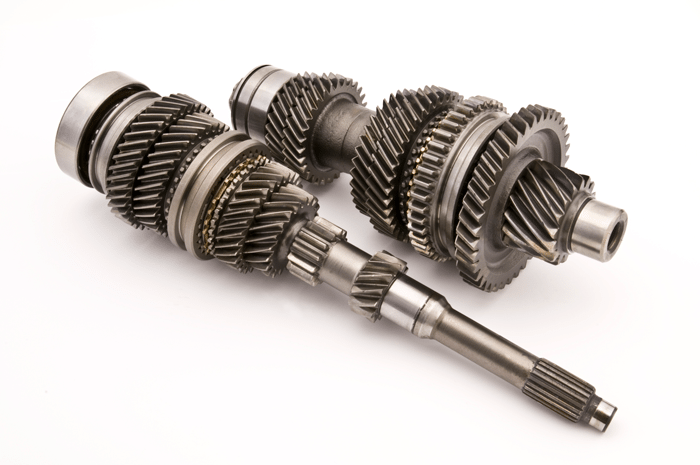

EXTRUDE HONE is pleased to welcome you to our stand at the DEBURRING EXPO, taking place from October 10th to 12th in Karlsruhe, Germany. You`ll find us in Hall 1, Booth 311. TEM meets burr removal requirements across internal passages, external features, cross-holes, and hard to reach areas in transmission shafts.

Burrs present on gear profiles, oil channels and cross-holes lead to contamination of the transmission oil resulting in failure. Manual deburring is time consuming, and always comes with costly post inspections to ensure part quality. The main challenge lies in ensuring that the shaft is 100 % burr free and free of loose metal particles from prior operations to ensure that there is no contamination of transmission oil.

Extrude Hone’s thermal deburring solution uses a mixture of natural gas and oxygen, which envelops the entire workpiece. This gaseous mixture, when ignited, results in combustion of burrs and other loose particles ensuring burr free components. Extrude Hone’s solution helps in achieving the most economical deburring by offering the right chamber size and fixtures.

Benefits:

- 100 % free of burrs and micro contamination

- Higher productivity in comparison to manual deburring

- Minimal post process inspection

- Subcontracting facilities available across regions as an alternative to capital investment

At the booth you can also ask us about the complete range of Extrude Hone solutions covering the 3 main technologies ECM, AFM, and TEM (Thermal deburring).